TURBINE FILTERS BUILT FOR THE LONG RUN.

In the oil and gas industry, gas turbines are the engines that provide power, steam and mechanical drive for oil and gas equipment. In order to run effectively and efficiently, they need to be free of salt, dust, and other contaminants.

Filtration is critical for turbine engines. If sub-micron particles, liquids and dissolved contaminants like air and water-borne salt aren’t captured by filters, they can enter the engine — resulting in compressor fouling and more severe problems like blocked cooling passages, blade erosion and hot gas corrosion. Ultimately, these issues can lead to lower power output, higher fuel consumption and more frequent repairs and replacement of high value parts.

GORE® Turbine Filters are used as air intake filters. They capture at least 99.5% of incoming contaminants and remove fine dust, salt crystals and even dissolved salts — thus greatly reducing the risk of power loss and shutdowns for compressor offline washings. Many turbines that use Gore filters have been running for tens of thousands of hours without the need for washing, resulting in big time and money savings.

Upgrading to GORE Turbine Filters with E12 hydrophobic HEPA technology has provided enormous value to rotating equipment users. These filters are designed to ensure a simple retrofit replacement of your current filters and in most cases, without filter house modifications. They deliver the greatest benefits to operators running intermediate and base load engines, who experience losses in compressor efficiency and power output due to fouling and who seek protection from corrosion due to salt ingestion. These systems are the high-usage, mission-critical engines where failure is not an option.

HOW IT WORKS.

E12 high-efficiency particulate air (HEPA) filters from Gore are engineered to keep your turbines up and running for the long haul. This durable watertight filtration technology is proven to:

- maintain clean engine performance

- minimize downtime

- lower maintenance costs over the filter’s lifetime

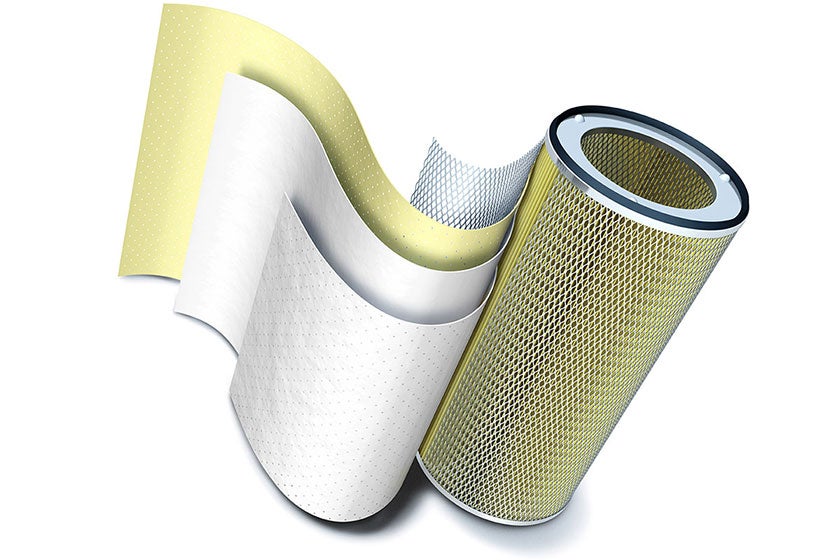

Gore’s proprietary thin, three-layer composite prescreens larger contaminants, captures smaller contaminants, and blocks water droplets with its naturally hydrophobic ePTFE (expanded polytetrafluoroethylene) membrane — allowing only pure air through.

By preventing ingestion of both dry and soluble contaminants, Gore’s HEPA technology practically eliminates compressor fouling over a long lifetime. Our uniquely engineered filters deliver the best ROI (return on investment) in challenging applications throughout many industries. You’ll notice the difference right away, but you’ll notice it even more in the long run.

E12 HEPA Classification

Filter performance ultimately comes down to the inherent characteristics of the filter media. The most important factors to consider when selecting a filter are efficiency, hydrophobicity, initial differential pressure (dP) and long-term dP (lifetime).

Only GORE Turbine Filters can offer industry-leading performance in all of these categories at once. This performance has been proven globally in the most challenging environments and delivers a positive economic ROI on gas turbines large and small.

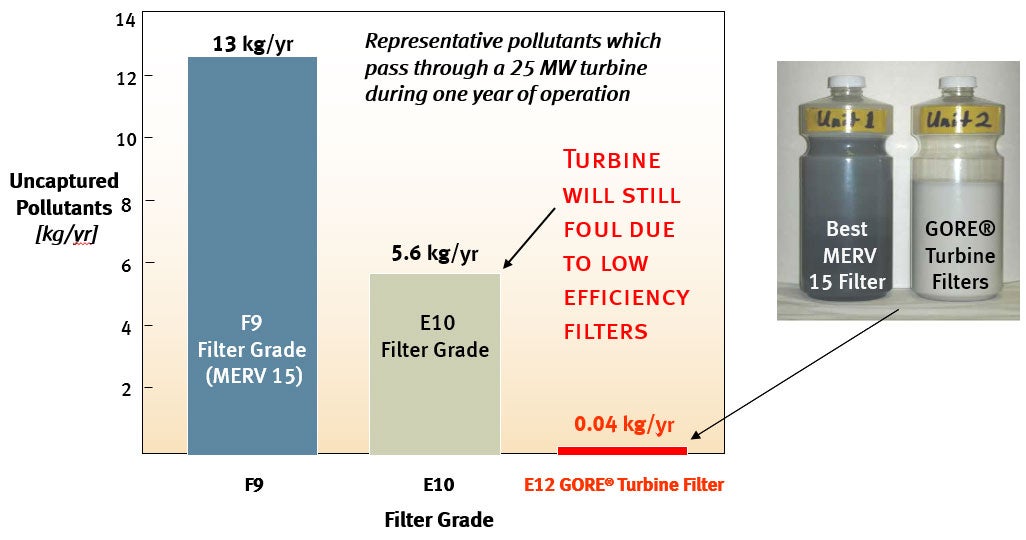

UNDERSTANDING HEPA HEPA is a classification of air filters. HEPA filters provide the highest level of filtration efficiency in the gas turbine industry. The grade of efficiency is determined by the most penetrating particle size (MPPS), which is the particle size most difficult for the filter to capture. These classifications are described in the European Standard EN 1822. GORE® Turbine Filters meet the filter classification of E12 according EN 1822 and have a minimum efficiency of 99.5% for the MPPS. By contrast, E10 filters capture only 85% of the MPPS. Other non-HEPA filter solutions may only capture 50% or even less.

PRODUCT OFFERINGS

Gore cartridge-style filters are able to be pulse-cleaned. Pulse cleaning can be very useful depending on the local environment. In cold-weather regions where ice can form on the filter and in dry regions with sand storms, on-demand pulsing can be very effective. Programming of the pulse system should be optimized for the application.

Pulse cleaning Gore filters is not required or beneficial in environments where icing or heavy sand loading isn’t present. Broad industry experience has shown that pulsing is ineffective at dislodging sticky submicron particles like hydrocarbons.

Compare GORE Turbine Filters

E12 vs. ALTERNATIVES

Not all HEPA filters deliver the same performance in the same applications or environmental conditions.

There are many variations of HEPA filter media being used in today’s gas turbine industry. Because these media types are composed of different fibers and layers, they work differently across various applications.

The filter media in GORE Turbine Filters is a three-layer composite that keeps fine particles, dirty water and salt out of the gas turbine. Key differences are noted in the following:

- efficiency

- filter lifetime

- material strength

- initial dP and long-term dP

- filter durability

- maximum dP limit

- water tightness

In our turbine filters’ patented structure, the three synthetic layers work in concert to deliver outstanding performance.

The first layer is a high-efficiency, non-woven material that prescreens the larger particles and captures contaminants throughout the depth of the structure.

The second layer is ePTFE, which captures very fine sub-micron particles that pass through the pre-filter layer. Additionally, the ePTFE membrane has a tight pore structure, which makes it naturally hydrophobic and blocks liquid water and dissolved salts and contaminants from passing through to the turbine, dramatically reducing fouling.

The third and final layer is a robust synthetic backing textile that provides rigidity and very high media burst resistance.

The resulting laminate delivers high efficiency and water protection with low dP and proven filter lifetime.

Why E12 vs. E11 or E10 Filter Classifications

E12 HEPA filters block >99.5%, allowing <0.5%, effectively eliminating compressor fouling. The combination of hydrophobicity and high-efficiency filtration found in GORE® Turbine Filters is key to protecting the turbine.

E10 HEPA filters only block 85% of the particles known to cause compressor fouling, allowing 15% to enter the turbine — significantly reducing compressor efficiency. Additionally, most E10 filters don’t eliminate water. Water carries salt (corrosion) and dirt (fouling) into the clean side of the turbine or compressor.

THERE ARE DIFFERENT HEPA RATINGS FOR A REASON.

BENEFITS

Our filters benefit turbine engines in numerous ways:

Reduce Turbine Wear

- Prevent blocking of cooling ports and overheating of blades

- Prevent rotational imbalance from compressor fouling

- Avoid cyclical thermal stress due to turbine stops and restarts for cleaning

Optimize Power Output

- Eliminate power loss from compressor fouling

- Eliminate fouling-induced heat rate increases

- Prevent captured contaminants from rinsing through filters during periods of heavy rain or fog

Increase Turbine Availability & Reliability

- Eliminate need for off-line compressor washing

- Avoid risk of startup and shutdown failures

- Operate continuously at clean compressor efficiency

Reduce Salt Corrosion

- Prevent liquid water ingress through filters.

- Stop penetration of airborne and waterborne salts.

- Reduce corrosion in compressor and hot section.

Delivers hydrophobic HEPA technology • E12 efficiency with pressure drop (∆P ) comparable to lower efficiency filters • Direct replacement for current filters • Proven lifetime in challenging environments

Photo: Taken on January 21, 2014First 3 stages of HPC Eng. SN 67610122K hours without Water Wash

Filter Lifetime

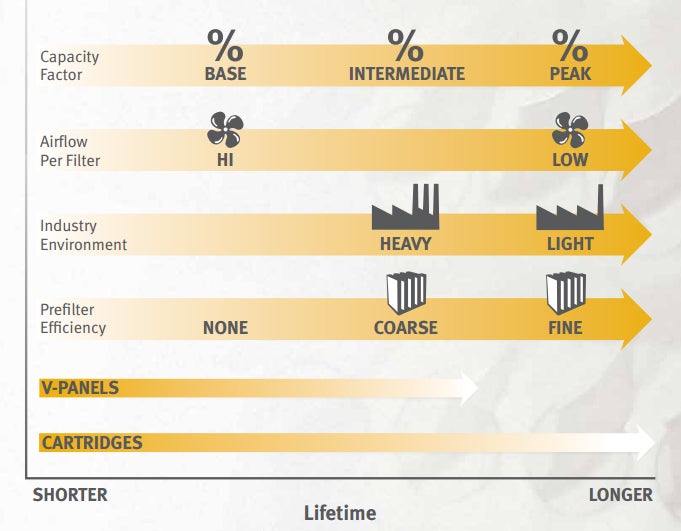

Turbine filter lifetime is subject to many variables. The first step to optimize E12 HEPA filter lifetime is to define your application.

- What type of inlet filters are you currently using and how long do they last?

- What is the overall airflow and flow per filter element?

- How many hours does the system run per year? Is the unit considered peak, intermediate or base-loaded?

- Are there local environmental challenges, such as heavy pollution, fog, insects or agricultural burning?

INFLUENCES AFFECTING FILTER LONGEVITY

- Lifetime is subject to many variables. The cases and data presented are from our experiences in the market and are for guidance only. Typically, cartridge filters have longer service life compared to panels due to common designs of filter houses.

Understanding HEPA Filter End of Life

It is important to understand what to expect when your E12 hydrophobic HEPA filters from Gore near the end of their service life.

HEPA filters are highly efficient and capture virtually all particles in an airstream over their lifetime. When the filters begin to approach end of life, ∆P trend monitoring will begin to show sensitivity to wet and humid conditions. However, the filters’ patented multi-layer construction delays this effect, enabling long lifetime even in challenging conditions.

GORE Turbine Filters have a proven lifetime of two to four years in very challenging coastal and industrial environments.

PRESSURE DROP TREND OVER FILTER LIFETIME

Trend monitoring of filter ΔP is the most reliable way to decide when to replace filters. This chart depicts the typical ΔP profile over the service life of a GORE Turbine Filter. When the ΔP trends upward and the influence of humidity grows, it is time to plan for filter replacement.

*Lifetime is subject to many variables. The cases and data presented are from our experiences in the market and are for guidance only.